AMIT ELECTRICALS

- Vatva, Ahmedabad - 382445 GUJARAT (INDIA)

- +91 - 9824003939

- info@amitelectricals.com

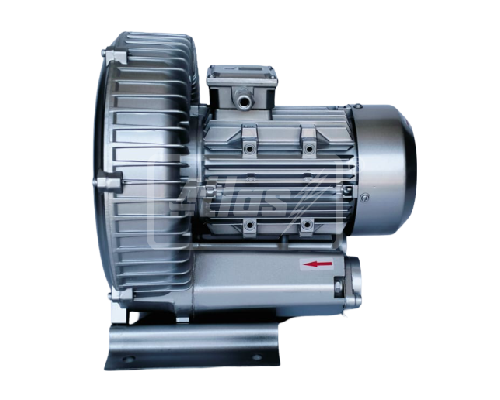

Ring Blower

Contact with us for any Information Or Inquiry

Need help? Talk to an expert

+91 - 9824003939Ring Blower

Amit electricals are manufacturer, Supplier and Exporter of Ring Blower In brand "ATLAS". It also knows as regenerative blower or side channel blower, is a device used to create airflow for various industrial and commercial applications. It operates using centrifugal force, where a high-speed impeller spins within a housing to generate continuous airflow.We are manufacturer Single stage and double stage Ring blower or side channel blower.

Specifications

Range of Production

We are having wide Product Range in Ring blower.

Three Phase

0.25 To 10 Hp. (0.18 to 7.5 Kw) Three Phase Ring blower suitable for 415 ± 5% volts 50 HZ ± 3%. We are also capable for Manufacturing three phase motor in different volts Like 220, 380, 460, 525 and 50 or 60 frequencies. Ring blowers are designed to operate at high pressure compared to standard centrifugal fans. The maximum pressure they can achieve typically ranges from 100 to 650 mbar

Single phase

0.25 To 2 H.P. (0.18. to 1.5 Kw) Single Phase Ring blower suitable for 215 ± 5% volts 50 HZ ± 3% we are also able to Supply motor in 110 volts on HZ 60 Also.

Impeller

A high-speed rotating impeller with radial blades is the core of the blower. It is usually made of lightweight yet durable materials like aluminum alloy.

Housing

The impeller is enclosed in a precisely designed housing, which forms the side channel. This housing is often pressure die-cast for strength and durability.

Inlet and Outlet Ports

These ports allow air to enter and exit the blower. They are usually threaded and equipped with silencers to reduce noise

Bearings and Seals

The impeller is supported by bearings, which are often self-lubricating. Seals are used to prevent air leakage and ensure efficient operation

Winding Insulation

Ring blower Winding are protected with insulated with class 'F'. Fully impregnated with high-grade insulating varnish for tropical climate.

Duty

Ring blowers are Design for Working Continuous (S1) rated to comply with performance standards.

Application

Ring blowers are Use in Number of applications Like Air circulation in HVAC systems , Air circulation in HVAC systems, Air circulation in irrigation systems, Dust control in industrial settings, Vacuum systems for packaging and printing, Cooling and drying machinery or components Medical equipment support Ect.

Features

- High efficient

- Compact design

- Economical price

- Long Life

- Durable

- Smooth finishing

- Precision design