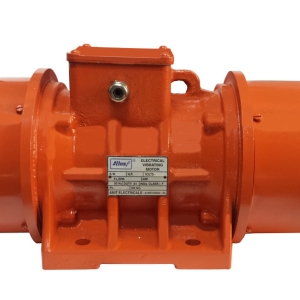

Vibrating Motors

Amit Electricals Manufacturer, Exporter and Supplier of Vibrating Motors. The external vibrator is a three-phase or single phase synchronous motor that has eccentric weights (unbalance weight) mounted at the ends of the Rotor shaft. The rotating shaft causes centrifugal forces, which can be adjusted by moving the weights it create a vibration. It also call Vibratory motor, Unbalance Motor, vibro motor, vibrates motor Ect. Vibration Help Many Way in Machine Application like Compacting, conveyor, assorting ect.

Specifications:

Range Of Production

Three Phase Motor

We having wide production range of vibrating motor 0.10 to 15 Hp. (0.075 to 11 K.W.) in 2, 4, 6, 8, 10 & 12 Pole. In Three Phase Vibrating motor Supply volts 415 ± 5% 3 phase 50 Hz. ± 3% we are also capable for manufacturing vibrating motor in different volts and frequency Like 220, 380, 460, 525.

Single Phase Motor

0.25 H.P. TO 2 H.P. in 2,4 pole 1 phase supply volts 215 ± 5% 50Hz. ± 5% on customer request we are also able supply motor in 110 volts on 50 or 60 Hz Also.

Mounting Type

- Foot

- Flange

- Center Flange

Frame

All Vibrating motor are supplied in a robust, rugged steel casting frame with integral feet.

Ratings

All Center Flange Vibratory Motor are continuous (S1) rated.

Design

The external Center Flange Vibratory Motor is a three-phase synchronous motor that has eccentric weights (unbalance weight) mounted at the ends of the Rotor shaft. The rotating shaft causes centrifugal forces, which can be adjusted by moving the weights it create a vibration.

Vibration Proof Motor Winding

Center Flange Vibratory Motor Insulation class F enhances the safety under continuous operation conditions and at high ambient temperatures. Motor are tropicalized and designed for an extended voltage range.

Protection

We are supply motor with Ingress protection 44. Vibrating Motors can be supplied with IP-54 and IP-55 on request.

Insulation

Vibrating motor are supply with class B & F insulation as standard feature. Also supply H on request of customer.

Rotor

All Vibrating motor Rotors are of high-pressure E.C. Grad aluminum die-cast. Every rotor is dynamically balanced. It’s make motor low amplitudes of Vibration & noise

Shaft

Shaft made from high carbon steel to provide exceptional Strength & rigidity to minimize deflection. Motor Rotor is positive locking with joint so that cannot move on high Full lord Torque.

Bearing and Lubrication

Vibratory Motors the right type of bearing for every application guarantees long service life even continuous operation. All vibratory motors are permanently lubricated for normal operation. Large capacity motor can be re-lubricated for average application. Sp. Type of grease is used in vibratory motor.

Enclosure

Vibrating motor Supply with Enclosure T.E.S.C. (Totally Enclosed surface Cooled)

Thermal Overload Protection

We can also supply motor with T.O.P Switch on Demand of Customer. It can provide motor extra safety form over lord protection.

Earthing Terminals

All Vibrating motor provided with minimum two earthling terminals. One in the terminal box and other on foot.

Paints

All Vibrating motor are painted with semi glossy synthetic enamel paint. However sp. Paint is available on request.

Application

Mining Industry, Food Industries, Construction, Parma industries, ceramic Industries, Foundry, Steel Industries, Chemical Industries, Recycling industries, Plastic Industries, Ect.

Features

- High efficient

- Durable

- Smooth finishing

- Economical price

- Precision design

- Long Life